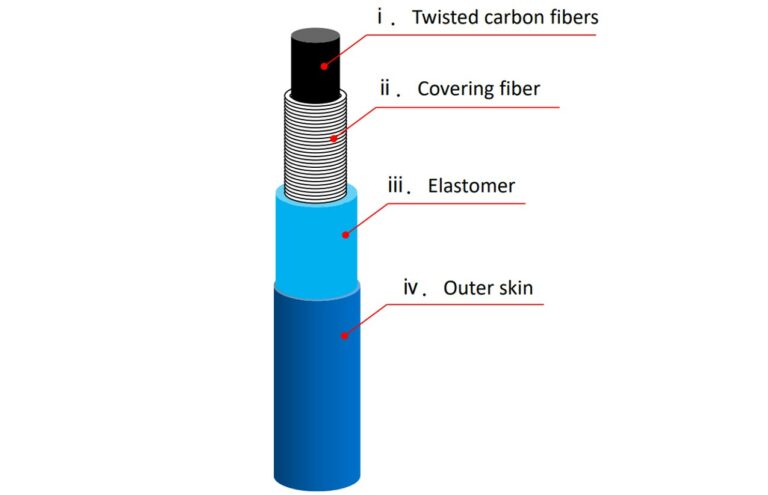

FLEXIBLE CARBON WIRE

ⅰ.Twisting process improves bending resistance of carbon fibers.

Multiple types of carbon fibers can be employed.

(ex. Toray, Teijin, Mitsubishi, 3k, 6k, 12k etc…)

ⅱ.Covering process enhances the strength of the carbon fiber bundle.

Any synthetic fibers or recycled fibers are applicable.

(ex. PET, PA6, Re-PET, Re-PA6, Dyneema etc…)

ⅲ.Impregnated elastomer brings flexibility.

To reduce environmental damage, this elastomer is

formed in water without organic solvent.(ex. SBR, NBR, PU etc…)

ⅳ.Outer skin enables wire slide smoothly and protected to friction.

Developing high performance and sustainable skin

by using bio-based PA and so on.(ex. PVC, Olefin, PA12, BIO-PA etc…)

By carbon wire’s advantages “Light, High Strength, Flexible, High corrosion resistance etc…”, our aim is to solve the various problems that conventional wires never solved.